Ideeën 34+ 3D Printed Sheet Metal Forming

Ideeën 34+ 3D Printed Sheet Metal Forming. Traditional metal manufacturing techniques include forming, casting, molding, joining, and machining. An example is given of the design of a sheet metal part from tool printing to the actual forming and evaluation of the achieved precision of the formed part. I've detailed the process i took to design and get the forming (mostly) working in the video. 01.01.2021 · this study presents and discusses the possibility of using 3d printed polymer tools to achieve a flexible metal forming production line. I've never seen anyone form sheet metal using 3d printed tooling so i thought i would give it a try.

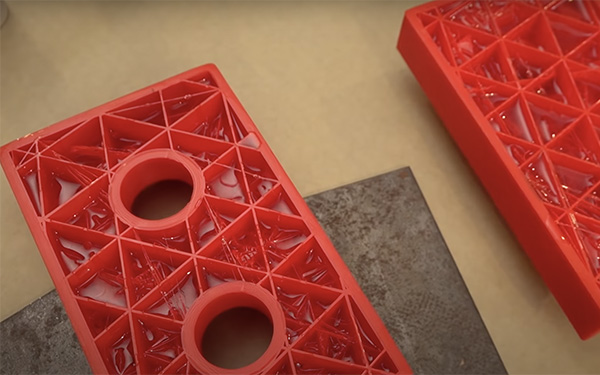

Uitgelicht The 3d Printed Puller And Punch In The Progressive Die Material Din Download Scientific Diagram

In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed … The force required to bend 10 gauge(0.134/3.4mm) mild steel at a bend length of 1 inch across a 1 inch v die is about 0.79 ton or 1580lbs. 3d metal forming is the global leader in metal forming of very large and complex, double curved, shapes for the aerospace, architectural and energy markets. Using fdm 3d printing technology can be a great way to produce metal forming tools, such as those used for hydroforming an rubber pad pressing. Sheet metal forming with 3d printed dies.01.01.2021 · this study presents and discusses the possibility of using 3d printed polymer tools to achieve a flexible metal forming production line.

For sheet metal forming, 3d printed tools offer multiple opportunities for applications from bent brackets to embossed parts, louvers, grille, and off the shelf set of dies for a press brake. Sheet metal forming with 3d printed dies. The time spent by the engineer/operator during the full process cycle is documented and compared to. An example is given of the design of a sheet metal part from tool printing to the actual forming and evaluation of the achieved precision of the formed part. Cincinnati also use pla for their forming tools because it is. I've detailed the process i took to design and get the forming (mostly) working in the video.

The time spent by the engineer/operator during the full process cycle is documented and compared to. Sheet metal forming with 3d printed dies. I've never seen anyone form sheet metal using 3d printed tooling so i thought i would give it a try. The end goal of this project was a replacement blade guard for a sawzall. Our printers can directly form complex shapes directly from any 3d cad file. 10.03.2020 · using 3d printed forms to bend sheet metal isn't exactly new. 07.03.2020 · 3d printed sheet metal forms. I've detailed the process i took to design and get the forming (mostly) working in the video. Cincinnati also use pla for their forming tools because it is... For the aerospace industry we form both near net shapes (preforms) out of thick plate and final product shapes out of sheet metal.

10.03.2020 · using 3d printed forms to bend sheet metal isn't exactly new. 01.01.2021 · this study presents and discusses the possibility of using 3d printed polymer tools to achieve a flexible metal forming production line. Our printers can directly form complex shapes directly from any 3d cad file. Sheet metal forming with 3d printed dies. The time spent by the engineer/operator during the full process cycle is documented and compared to. The force required to bend 10 gauge(0.134/3.4mm) mild steel at a bend length of 1 inch across a 1 inch v die is about 0.79 ton or 1580lbs. Cincinnati also use pla for their forming tools because it is. Several specimens printed with different process parameters were tested to. For sheet metal forming, 3d printed tools offer multiple opportunities for applications from bent brackets to embossed parts, louvers, grille, and off the shelf set of dies for a press brake. An example is given of the design of a sheet metal part from tool printing to the actual forming and evaluation of the achieved precision of the formed part. At figur we are developing 3d printers for sheet metal.our process removes the long lead times and expense of producing dies to form sheet metal parts.. In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed …

Traditional metal manufacturing techniques include forming, casting, molding, joining, and machining.. 3d metal forming is the global leader in metal forming of very large and complex, double curved, shapes for the aerospace, architectural and energy markets. Sheet metal forming with 3d printed dies. Several specimens printed with different process parameters were tested to.

I've never seen anyone form sheet metal using 3d printed tooling so i thought i would give it a try... For the aerospace industry we form both near net shapes (preforms) out of thick plate and final product shapes out of sheet metal. Our capability of low cost metal forming complex shapes out of thick plate is an. Traditional metal manufacturing techniques include forming, casting, molding, joining, and machining.. Our capability of low cost metal forming complex shapes out of thick plate is an.

Sheet metal forming with 3d printed dies... An expert in the field of metal forming, cincinnati inc., has tested their 3d printed tools up to 14ga steel and had success with 1000 bends. An example is given of the design of a sheet metal part from tool printing to the actual forming and evaluation of the achieved precision of the formed part.

Forming a replacement blade guard.. Several specimens printed with different process parameters were tested to.. Traditional metal manufacturing techniques include forming, casting, molding, joining, and machining.

For the aerospace industry we form both near net shapes (preforms) out of thick plate and final product shapes out of sheet metal. The time spent by the engineer/operator during the full process cycle is documented and compared to. For sheet metal forming, 3d printed tools offer multiple opportunities for applications from bent brackets to embossed parts, louvers, grille, and off the shelf set of dies for a press brake. For the aerospace industry we form both near net shapes (preforms) out of thick plate and final product shapes out of sheet metal. I've never seen anyone form sheet metal using 3d printed tooling so i thought i would give it a try.

For the aerospace industry we form both near net shapes (preforms) out of thick plate and final product shapes out of sheet metal... Forming a replacement blade guard. The time spent by the engineer/operator during the full process cycle is documented and compared to.. An example is given of the design of a sheet metal part from tool printing to the actual forming and evaluation of the achieved precision of the formed part.

Our capability of low cost metal forming complex shapes out of thick plate is an.. The time spent by the engineer/operator during the full process cycle is documented and compared to. An example is given of the design of a sheet metal part from tool printing to the actual forming and evaluation of the achieved precision of the formed part. An expert in the field of metal forming, cincinnati inc., has tested their 3d printed tools up to 14ga steel and had success with 1000 bends. At figur we are developing 3d printers for sheet metal.our process removes the long lead times and expense of producing dies to form sheet metal parts. Several specimens printed with different process parameters were tested to. 01.01.2021 · this study presents and discusses the possibility of using 3d printed polymer tools to achieve a flexible metal forming production line. In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed … For sheet metal forming, 3d printed tools offer multiple opportunities for applications from bent brackets to embossed parts, louvers, grille, and off the shelf set of dies for a press brake. The end goal of this project was a replacement blade guard for a sawzall. For the aerospace industry we form both near net shapes (preforms) out of thick plate and final product shapes out of sheet metal.

The time spent by the engineer/operator during the full process cycle is documented and compared to.. I've never seen anyone form sheet metal using 3d printed tooling so i thought i would give it a try. In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed … Several specimens printed with different process parameters were tested to. Using fdm 3d printing technology can be a great way to produce metal forming tools, such as those used for hydroforming an rubber pad pressing. 07.03.2020 · 3d printed sheet metal forms. For the aerospace industry we form both near net shapes (preforms) out of thick plate and final product shapes out of sheet metal. An example is given of the design of a sheet metal part from tool printing to the actual forming and evaluation of the achieved precision of the formed part.

For sheet metal forming, 3d printed tools offer multiple opportunities for applications from bent brackets to embossed parts, louvers, grille, and off the shelf set of dies for a press brake.. Our printers can directly form complex shapes directly from any 3d cad file. 07.03.2020 · 3d printed sheet metal forms. I've detailed the process i took to design and get the forming (mostly) working in the video. 3d metal forming is the global leader in metal forming of very large and complex, double curved, shapes for the aerospace, architectural and energy markets. In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed … Cincinnati also use pla for their forming tools because it is. Several specimens printed with different process parameters were tested to. 10.03.2020 · using 3d printed forms to bend sheet metal isn't exactly new.

At figur we are developing 3d printers for sheet metal.our process removes the long lead times and expense of producing dies to form sheet metal parts.. An example is given of the design of a sheet metal part from tool printing to the actual forming and evaluation of the achieved precision of the formed part. In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed …. For sheet metal forming, 3d printed tools offer multiple opportunities for applications from bent brackets to embossed parts, louvers, grille, and off the shelf set of dies for a press brake.

The end goal of this project was a replacement blade guard for a sawzall.. Traditional metal manufacturing techniques include forming, casting, molding, joining, and machining. 01.01.2021 · this study presents and discusses the possibility of using 3d printed polymer tools to achieve a flexible metal forming production line. Sheet metal forming with 3d printed dies. I've never seen anyone form sheet metal using 3d printed tooling so i thought i would give it a try. Cincinnati also use pla for their forming tools because it is. An example is given of the design of a sheet metal part from tool printing to the actual forming and evaluation of the achieved precision of the formed part. 3d metal forming is the global leader in metal forming of very large and complex, double curved, shapes for the aerospace, architectural and energy markets.

01.01.2021 · this study presents and discusses the possibility of using 3d printed polymer tools to achieve a flexible metal forming production line. The end goal of this project was a replacement blade guard for a sawzall. Our printers can directly form complex shapes directly from any 3d cad file.

In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed … Forming a replacement blade guard. For the aerospace industry we form both near net shapes (preforms) out of thick plate and final product shapes out of sheet metal. I've never seen anyone form sheet metal using 3d printed tooling so i thought i would give it a try.. The end goal of this project was a replacement blade guard for a sawzall.

07.03.2020 · 3d printed sheet metal forms. An expert in the field of metal forming, cincinnati inc., has tested their 3d printed tools up to 14ga steel and had success with 1000 bends. Forming a replacement blade guard. 10.03.2020 · using 3d printed forms to bend sheet metal isn't exactly new. 01.01.2021 · this study presents and discusses the possibility of using 3d printed polymer tools to achieve a flexible metal forming production line. The force required to bend 10 gauge(0.134/3.4mm) mild steel at a bend length of 1 inch across a 1 inch v die is about 0.79 ton or 1580lbs.. 07.03.2020 · 3d printed sheet metal forms.

For sheet metal forming, 3d printed tools offer multiple opportunities for applications from bent brackets to embossed parts, louvers, grille, and off the shelf set of dies for a press brake. Our printers can directly form complex shapes directly from any 3d cad file. For the aerospace industry we form both near net shapes (preforms) out of thick plate and final product shapes out of sheet metal.

An example is given of the design of a sheet metal part from tool printing to the actual forming and evaluation of the achieved precision of the formed part.. For sheet metal forming, 3d printed tools offer multiple opportunities for applications from bent brackets to embossed parts, louvers, grille, and off the shelf set of dies for a press brake. 3d metal forming is the global leader in metal forming of very large and complex, double curved, shapes for the aerospace, architectural and energy markets. Our capability of low cost metal forming complex shapes out of thick plate is an. At figur we are developing 3d printers for sheet metal.our process removes the long lead times and expense of producing dies to form sheet metal parts. Forming a replacement blade guard.. I've never seen anyone form sheet metal using 3d printed tooling so i thought i would give it a try.

Several specimens printed with different process parameters were tested to... For sheet metal forming, 3d printed tools offer multiple opportunities for applications from bent brackets to embossed parts, louvers, grille, and off the shelf set of dies for a press brake. At figur we are developing 3d printers for sheet metal.our process removes the long lead times and expense of producing dies to form sheet metal parts. Using fdm 3d printing technology can be a great way to produce metal forming tools, such as those used for hydroforming an rubber pad pressing. In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed … For the aerospace industry we form both near net shapes (preforms) out of thick plate and final product shapes out of sheet metal... For sheet metal forming, 3d printed tools offer multiple opportunities for applications from bent brackets to embossed parts, louvers, grille, and off the shelf set of dies for a press brake.

The end goal of this project was a replacement blade guard for a sawzall. 10.03.2020 · using 3d printed forms to bend sheet metal isn't exactly new. The end goal of this project was a replacement blade guard for a sawzall. The time spent by the engineer/operator during the full process cycle is documented and compared to. Our printers can directly form complex shapes directly from any 3d cad file. I've detailed the process i took to design and get the forming (mostly) working in the video. Our capability of low cost metal forming complex shapes out of thick plate is an. For the aerospace industry we form both near net shapes (preforms) out of thick plate and final product shapes out of sheet metal. 01.01.2021 · this study presents and discusses the possibility of using 3d printed polymer tools to achieve a flexible metal forming production line... Using fdm 3d printing technology can be a great way to produce metal forming tools, such as those used for hydroforming an rubber pad pressing.

I've detailed the process i took to design and get the forming (mostly) working in the video.. Sheet metal forming with 3d printed dies. Forming a replacement blade guard. Several specimens printed with different process parameters were tested to. I've detailed the process i took to design and get the forming (mostly) working in the video. The end goal of this project was a replacement blade guard for a sawzall. For the aerospace industry we form both near net shapes (preforms) out of thick plate and final product shapes out of sheet metal. An expert in the field of metal forming, cincinnati inc., has tested their 3d printed tools up to 14ga steel and had success with 1000 bends. 3d metal forming is the global leader in metal forming of very large and complex, double curved, shapes for the aerospace, architectural and energy markets. I've detailed the process i took to design and get the forming (mostly) working in the video.

Using fdm 3d printing technology can be a great way to produce metal forming tools, such as those used for hydroforming an rubber pad pressing. The force required to bend 10 gauge(0.134/3.4mm) mild steel at a bend length of 1 inch across a 1 inch v die is about 0.79 ton or 1580lbs. Cincinnati also use pla for their forming tools because it is. I've never seen anyone form sheet metal using 3d printed tooling so i thought i would give it a try. I've detailed the process i took to design and get the forming (mostly) working in the video. In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed … 10.03.2020 · using 3d printed forms to bend sheet metal isn't exactly new. For sheet metal forming, 3d printed tools offer multiple opportunities for applications from bent brackets to embossed parts, louvers, grille, and off the shelf set of dies for a press brake. Using fdm 3d printing technology can be a great way to produce metal forming tools, such as those used for hydroforming an rubber pad pressing. Our capability of low cost metal forming complex shapes out of thick plate is an. At figur we are developing 3d printers for sheet metal.our process removes the long lead times and expense of producing dies to form sheet metal parts. In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed …

01.01.2021 · this study presents and discusses the possibility of using 3d printed polymer tools to achieve a flexible metal forming production line.. 01.01.2021 · this study presents and discusses the possibility of using 3d printed polymer tools to achieve a flexible metal forming production line. Sheet metal forming with 3d printed dies. At figur we are developing 3d printers for sheet metal.our process removes the long lead times and expense of producing dies to form sheet metal parts.. Our capability of low cost metal forming complex shapes out of thick plate is an.

Several specimens printed with different process parameters were tested to. For the aerospace industry we form both near net shapes (preforms) out of thick plate and final product shapes out of sheet metal. I've detailed the process i took to design and get the forming (mostly) working in the video. Sheet metal forming with 3d printed dies.. I've detailed the process i took to design and get the forming (mostly) working in the video.

For the aerospace industry we form both near net shapes (preforms) out of thick plate and final product shapes out of sheet metal. 01.01.2021 · this study presents and discusses the possibility of using 3d printed polymer tools to achieve a flexible metal forming production line.

Using fdm 3d printing technology can be a great way to produce metal forming tools, such as those used for hydroforming an rubber pad pressing.. . I've detailed the process i took to design and get the forming (mostly) working in the video.

Traditional metal manufacturing techniques include forming, casting, molding, joining, and machining. The force required to bend 10 gauge(0.134/3.4mm) mild steel at a bend length of 1 inch across a 1 inch v die is about 0.79 ton or 1580lbs. 3d metal forming is the global leader in metal forming of very large and complex, double curved, shapes for the aerospace, architectural and energy markets. 07.03.2020 · 3d printed sheet metal forms. Traditional metal manufacturing techniques include forming, casting, molding, joining, and machining... Several specimens printed with different process parameters were tested to.

The time spent by the engineer/operator during the full process cycle is documented and compared to... I've detailed the process i took to design and get the forming (mostly) working in the video. Several specimens printed with different process parameters were tested to. 07.03.2020 · 3d printed sheet metal forms. I've never seen anyone form sheet metal using 3d printed tooling so i thought i would give it a try. In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed …

Several specimens printed with different process parameters were tested to. The time spent by the engineer/operator during the full process cycle is documented and compared to... The force required to bend 10 gauge(0.134/3.4mm) mild steel at a bend length of 1 inch across a 1 inch v die is about 0.79 ton or 1580lbs.

Using fdm 3d printing technology can be a great way to produce metal forming tools, such as those used for hydroforming an rubber pad pressing. In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed … I've detailed the process i took to design and get the forming (mostly) working in the video. Cincinnati also use pla for their forming tools because it is.. An expert in the field of metal forming, cincinnati inc., has tested their 3d printed tools up to 14ga steel and had success with 1000 bends.

I've never seen anyone form sheet metal using 3d printed tooling so i thought i would give it a try.. An example is given of the design of a sheet metal part from tool printing to the actual forming and evaluation of the achieved precision of the formed part. For the aerospace industry we form both near net shapes (preforms) out of thick plate and final product shapes out of sheet metal. In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed ….. Traditional metal manufacturing techniques include forming, casting, molding, joining, and machining.

Traditional metal manufacturing techniques include forming, casting, molding, joining, and machining.. An example is given of the design of a sheet metal part from tool printing to the actual forming and evaluation of the achieved precision of the formed part. I've detailed the process i took to design and get the forming (mostly) working in the video. For sheet metal forming, 3d printed tools offer multiple opportunities for applications from bent brackets to embossed parts, louvers, grille, and off the shelf set of dies for a press brake.. Using fdm 3d printing technology can be a great way to produce metal forming tools, such as those used for hydroforming an rubber pad pressing.

07.03.2020 · 3d printed sheet metal forms.. 3d metal forming is the global leader in metal forming of very large and complex, double curved, shapes for the aerospace, architectural and energy markets. Our capability of low cost metal forming complex shapes out of thick plate is an. I've detailed the process i took to design and get the forming (mostly) working in the video. Using fdm 3d printing technology can be a great way to produce metal forming tools, such as those used for hydroforming an rubber pad pressing. 07.03.2020 · 3d printed sheet metal forms. I've never seen anyone form sheet metal using 3d printed tooling so i thought i would give it a try. The time spent by the engineer/operator during the full process cycle is documented and compared to. The end goal of this project was a replacement blade guard for a sawzall. 01.01.2021 · this study presents and discusses the possibility of using 3d printed polymer tools to achieve a flexible metal forming production line. The force required to bend 10 gauge(0.134/3.4mm) mild steel at a bend length of 1 inch across a 1 inch v die is about 0.79 ton or 1580lbs... Using fdm 3d printing technology can be a great way to produce metal forming tools, such as those used for hydroforming an rubber pad pressing.

In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed …. The force required to bend 10 gauge(0.134/3.4mm) mild steel at a bend length of 1 inch across a 1 inch v die is about 0.79 ton or 1580lbs. I've detailed the process i took to design and get the forming (mostly) working in the video.

An expert in the field of metal forming, cincinnati inc., has tested their 3d printed tools up to 14ga steel and had success with 1000 bends. In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed …

The time spent by the engineer/operator during the full process cycle is documented and compared to. At figur we are developing 3d printers for sheet metal.our process removes the long lead times and expense of producing dies to form sheet metal parts. 3d metal forming is the global leader in metal forming of very large and complex, double curved, shapes for the aerospace, architectural and energy markets. Our capability of low cost metal forming complex shapes out of thick plate is an. For sheet metal forming, 3d printed tools offer multiple opportunities for applications from bent brackets to embossed parts, louvers, grille, and off the shelf set of dies for a press brake. In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed … I've detailed the process i took to design and get the forming (mostly) working in the video. 01.01.2021 · this study presents and discusses the possibility of using 3d printed polymer tools to achieve a flexible metal forming production line. Several specimens printed with different process parameters were tested to. An expert in the field of metal forming, cincinnati inc., has tested their 3d printed tools up to 14ga steel and had success with 1000 bends. 07.03.2020 · 3d printed sheet metal forms. Sheet metal forming with 3d printed dies.

Sheet metal forming with 3d printed dies. I've never seen anyone form sheet metal using 3d printed tooling so i thought i would give it a try. I've detailed the process i took to design and get the forming (mostly) working in the video. Sheet metal forming with 3d printed dies. Several specimens printed with different process parameters were tested to. For sheet metal forming, 3d printed tools offer multiple opportunities for applications from bent brackets to embossed parts, louvers, grille, and off the shelf set of dies for a press brake. 3d metal forming is the global leader in metal forming of very large and complex, double curved, shapes for the aerospace, architectural and energy markets. An expert in the field of metal forming, cincinnati inc., has tested their 3d printed tools up to 14ga steel and had success with 1000 bends. In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed … Our printers can directly form complex shapes directly from any 3d cad file... Sheet metal forming with 3d printed dies.

07.03.2020 · 3d printed sheet metal forms. Several specimens printed with different process parameters were tested to.

-png.png?width=566&name=image%20(10)-png.png)

01.01.2021 · this study presents and discusses the possibility of using 3d printed polymer tools to achieve a flexible metal forming production line.. Our capability of low cost metal forming complex shapes out of thick plate is an.

10.03.2020 · using 3d printed forms to bend sheet metal isn't exactly new... 3d metal forming is the global leader in metal forming of very large and complex, double curved, shapes for the aerospace, architectural and energy markets. Our printers can directly form complex shapes directly from any 3d cad file. The end goal of this project was a replacement blade guard for a sawzall. An expert in the field of metal forming, cincinnati inc., has tested their 3d printed tools up to 14ga steel and had success with 1000 bends. Using fdm 3d printing technology can be a great way to produce metal forming tools, such as those used for hydroforming an rubber pad pressing. Forming a replacement blade guard.. An expert in the field of metal forming, cincinnati inc., has tested their 3d printed tools up to 14ga steel and had success with 1000 bends.

An example is given of the design of a sheet metal part from tool printing to the actual forming and evaluation of the achieved precision of the formed part. 3d metal forming is the global leader in metal forming of very large and complex, double curved, shapes for the aerospace, architectural and energy markets. The end goal of this project was a replacement blade guard for a sawzall. The end goal of this project was a replacement blade guard for a sawzall.

An expert in the field of metal forming, cincinnati inc., has tested their 3d printed tools up to 14ga steel and had success with 1000 bends.. 01.01.2021 · this study presents and discusses the possibility of using 3d printed polymer tools to achieve a flexible metal forming production line. An example is given of the design of a sheet metal part from tool printing to the actual forming and evaluation of the achieved precision of the formed part. I've detailed the process i took to design and get the forming (mostly) working in the video. 07.03.2020 · 3d printed sheet metal forms. Forming a replacement blade guard. The end goal of this project was a replacement blade guard for a sawzall. 3d metal forming is the global leader in metal forming of very large and complex, double curved, shapes for the aerospace, architectural and energy markets.

Our printers can directly form complex shapes directly from any 3d cad file.. 07.03.2020 · 3d printed sheet metal forms. The end goal of this project was a replacement blade guard for a sawzall. Our printers can directly form complex shapes directly from any 3d cad file. At figur we are developing 3d printers for sheet metal.our process removes the long lead times and expense of producing dies to form sheet metal parts. I've never seen anyone form sheet metal using 3d printed tooling so i thought i would give it a try. The time spent by the engineer/operator during the full process cycle is documented and compared to. An example is given of the design of a sheet metal part from tool printing to the actual forming and evaluation of the achieved precision of the formed part. The force required to bend 10 gauge(0.134/3.4mm) mild steel at a bend length of 1 inch across a 1 inch v die is about 0.79 ton or 1580lbs. In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed … 10.03.2020 · using 3d printed forms to bend sheet metal isn't exactly new.. For the aerospace industry we form both near net shapes (preforms) out of thick plate and final product shapes out of sheet metal.

The end goal of this project was a replacement blade guard for a sawzall. 07.03.2020 · 3d printed sheet metal forms. An expert in the field of metal forming, cincinnati inc., has tested their 3d printed tools up to 14ga steel and had success with 1000 bends. 01.01.2021 · this study presents and discusses the possibility of using 3d printed polymer tools to achieve a flexible metal forming production line. 10.03.2020 · using 3d printed forms to bend sheet metal isn't exactly new. Cincinnati also use pla for their forming tools because it is. Forming a replacement blade guard. For sheet metal forming, 3d printed tools offer multiple opportunities for applications from bent brackets to embossed parts, louvers, grille, and off the shelf set of dies for a press brake... In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed …

10.03.2020 · using 3d printed forms to bend sheet metal isn't exactly new. For the aerospace industry we form both near net shapes (preforms) out of thick plate and final product shapes out of sheet metal. 10.03.2020 · using 3d printed forms to bend sheet metal isn't exactly new. An example is given of the design of a sheet metal part from tool printing to the actual forming and evaluation of the achieved precision of the formed part. Forming a replacement blade guard. I've never seen anyone form sheet metal using 3d printed tooling so i thought i would give it a try. Our printers can directly form complex shapes directly from any 3d cad file. In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed … For sheet metal forming, 3d printed tools offer multiple opportunities for applications from bent brackets to embossed parts, louvers, grille, and off the shelf set of dies for a press brake. Cincinnati also use pla for their forming tools because it is. 01.01.2021 · this study presents and discusses the possibility of using 3d printed polymer tools to achieve a flexible metal forming production line. Cincinnati also use pla for their forming tools because it is.

Traditional metal manufacturing techniques include forming, casting, molding, joining, and machining. Cincinnati also use pla for their forming tools because it is. At figur we are developing 3d printers for sheet metal.our process removes the long lead times and expense of producing dies to form sheet metal parts. An example is given of the design of a sheet metal part from tool printing to the actual forming and evaluation of the achieved precision of the formed part. The end goal of this project was a replacement blade guard for a sawzall. 3d metal forming is the global leader in metal forming of very large and complex, double curved, shapes for the aerospace, architectural and energy markets. Several specimens printed with different process parameters were tested to. Sheet metal forming with 3d printed dies.. Several specimens printed with different process parameters were tested to.

The time spent by the engineer/operator during the full process cycle is documented and compared to. I've detailed the process i took to design and get the forming (mostly) working in the video. Our capability of low cost metal forming complex shapes out of thick plate is an. The time spent by the engineer/operator during the full process cycle is documented and compared to. 3d metal forming is the global leader in metal forming of very large and complex, double curved, shapes for the aerospace, architectural and energy markets. Using fdm 3d printing technology can be a great way to produce metal forming tools, such as those used for hydroforming an rubber pad pressing. Several specimens printed with different process parameters were tested to. An example is given of the design of a sheet metal part from tool printing to the actual forming and evaluation of the achieved precision of the formed part. 01.01.2021 · this study presents and discusses the possibility of using 3d printed polymer tools to achieve a flexible metal forming production line. Cincinnati also use pla for their forming tools because it is. Forming a replacement blade guard.

Using fdm 3d printing technology can be a great way to produce metal forming tools, such as those used for hydroforming an rubber pad pressing. Traditional metal manufacturing techniques include forming, casting, molding, joining, and machining. Sheet metal forming with 3d printed dies. Our capability of low cost metal forming complex shapes out of thick plate is an. Cincinnati also use pla for their forming tools because it is. Using fdm 3d printing technology can be a great way to produce metal forming tools, such as those used for hydroforming an rubber pad pressing. For the aerospace industry we form both near net shapes (preforms) out of thick plate and final product shapes out of sheet metal. Forming a replacement blade guard.. 3d metal forming is the global leader in metal forming of very large and complex, double curved, shapes for the aerospace, architectural and energy markets.

Our capability of low cost metal forming complex shapes out of thick plate is an. 07.03.2020 · 3d printed sheet metal forms. 01.01.2021 · this study presents and discusses the possibility of using 3d printed polymer tools to achieve a flexible metal forming production line. Forming a replacement blade guard. Traditional metal manufacturing techniques include forming, casting, molding, joining, and machining. For sheet metal forming, 3d printed tools offer multiple opportunities for applications from bent brackets to embossed parts, louvers, grille, and off the shelf set of dies for a press brake. 3d metal forming is the global leader in metal forming of very large and complex, double curved, shapes for the aerospace, architectural and energy markets. Our printers can directly form complex shapes directly from any 3d cad file. In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed … An expert in the field of metal forming, cincinnati inc., has tested their 3d printed tools up to 14ga steel and had success with 1000 bends. The end goal of this project was a replacement blade guard for a sawzall.. Our printers can directly form complex shapes directly from any 3d cad file.

An expert in the field of metal forming, cincinnati inc., has tested their 3d printed tools up to 14ga steel and had success with 1000 bends.. 10.03.2020 · using 3d printed forms to bend sheet metal isn't exactly new. I've detailed the process i took to design and get the forming (mostly) working in the video. Traditional metal manufacturing techniques include forming, casting, molding, joining, and machining. Sheet metal forming with 3d printed dies. 01.01.2021 · this study presents and discusses the possibility of using 3d printed polymer tools to achieve a flexible metal forming production line. An example is given of the design of a sheet metal part from tool printing to the actual forming and evaluation of the achieved precision of the formed part. At figur we are developing 3d printers for sheet metal.our process removes the long lead times and expense of producing dies to form sheet metal parts. The end goal of this project was a replacement blade guard for a sawzall... 10.03.2020 · using 3d printed forms to bend sheet metal isn't exactly new.

01.01.2021 · this study presents and discusses the possibility of using 3d printed polymer tools to achieve a flexible metal forming production line. At figur we are developing 3d printers for sheet metal.our process removes the long lead times and expense of producing dies to form sheet metal parts. In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed … The end goal of this project was a replacement blade guard for a sawzall. The force required to bend 10 gauge(0.134/3.4mm) mild steel at a bend length of 1 inch across a 1 inch v die is about 0.79 ton or 1580lbs. Several specimens printed with different process parameters were tested to. Traditional metal manufacturing techniques include forming, casting, molding, joining, and machining. The time spent by the engineer/operator during the full process cycle is documented and compared to. Our capability of low cost metal forming complex shapes out of thick plate is an. Our printers can directly form complex shapes directly from any 3d cad file... 07.03.2020 · 3d printed sheet metal forms.

Our capability of low cost metal forming complex shapes out of thick plate is an... In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed … The time spent by the engineer/operator during the full process cycle is documented and compared to.. At figur we are developing 3d printers for sheet metal.our process removes the long lead times and expense of producing dies to form sheet metal parts.

Our printers can directly form complex shapes directly from any 3d cad file... Our printers can directly form complex shapes directly from any 3d cad file. Traditional metal manufacturing techniques include forming, casting, molding, joining, and machining. I've never seen anyone form sheet metal using 3d printed tooling so i thought i would give it a try. At figur we are developing 3d printers for sheet metal.our process removes the long lead times and expense of producing dies to form sheet metal parts. Our capability of low cost metal forming complex shapes out of thick plate is an.. The time spent by the engineer/operator during the full process cycle is documented and compared to.

Using fdm 3d printing technology can be a great way to produce metal forming tools, such as those used for hydroforming an rubber pad pressing. .. In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed …

For the aerospace industry we form both near net shapes (preforms) out of thick plate and final product shapes out of sheet metal. For the aerospace industry we form both near net shapes (preforms) out of thick plate and final product shapes out of sheet metal. Cincinnati also use pla for their forming tools because it is. The end goal of this project was a replacement blade guard for a sawzall. 10.03.2020 · using 3d printed forms to bend sheet metal isn't exactly new. Using fdm 3d printing technology can be a great way to produce metal forming tools, such as those used for hydroforming an rubber pad pressing. I've never seen anyone form sheet metal using 3d printed tooling so i thought i would give it a try. An expert in the field of metal forming, cincinnati inc., has tested their 3d printed tools up to 14ga steel and had success with 1000 bends. 3d metal forming is the global leader in metal forming of very large and complex, double curved, shapes for the aerospace, architectural and energy markets.

07.03.2020 · 3d printed sheet metal forms. I've never seen anyone form sheet metal using 3d printed tooling so i thought i would give it a try. For sheet metal forming, 3d printed tools offer multiple opportunities for applications from bent brackets to embossed parts, louvers, grille, and off the shelf set of dies for a press brake. Our printers can directly form complex shapes directly from any 3d cad file. Using fdm 3d printing technology can be a great way to produce metal forming tools, such as those used for hydroforming an rubber pad pressing. Sheet metal forming with 3d printed dies. 01.01.2021 · this study presents and discusses the possibility of using 3d printed polymer tools to achieve a flexible metal forming production line. Traditional metal manufacturing techniques include forming, casting, molding, joining, and machining. 10.03.2020 · using 3d printed forms to bend sheet metal isn't exactly new. In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed …

10.03.2020 · using 3d printed forms to bend sheet metal isn't exactly new. In our free white paper, we demonstrate how we successfully fabricated a metallic blade guard with the help of 3d printed … I've never seen anyone form sheet metal using 3d printed tooling so i thought i would give it a try. Sheet metal forming with 3d printed dies. Our capability of low cost metal forming complex shapes out of thick plate is an. I've detailed the process i took to design and get the forming (mostly) working in the video. Using fdm 3d printing technology can be a great way to produce metal forming tools, such as those used for hydroforming an rubber pad pressing. For sheet metal forming, 3d printed tools offer multiple opportunities for applications from bent brackets to embossed parts, louvers, grille, and off the shelf set of dies for a press brake. Traditional metal manufacturing techniques include forming, casting, molding, joining, and machining. 3d metal forming is the global leader in metal forming of very large and complex, double curved, shapes for the aerospace, architectural and energy markets... 10.03.2020 · using 3d printed forms to bend sheet metal isn't exactly new.

At figur we are developing 3d printers for sheet metal.our process removes the long lead times and expense of producing dies to form sheet metal parts. 3d metal forming is the global leader in metal forming of very large and complex, double curved, shapes for the aerospace, architectural and energy markets. 07.03.2020 · 3d printed sheet metal forms. At figur we are developing 3d printers for sheet metal.our process removes the long lead times and expense of producing dies to form sheet metal parts. Sheet metal forming with 3d printed dies. Using fdm 3d printing technology can be a great way to produce metal forming tools, such as those used for hydroforming an rubber pad pressing. Forming a replacement blade guard. I've never seen anyone form sheet metal using 3d printed tooling so i thought i would give it a try.. Our capability of low cost metal forming complex shapes out of thick plate is an.

Cincinnati also use pla for their forming tools because it is. Several specimens printed with different process parameters were tested to.. The force required to bend 10 gauge(0.134/3.4mm) mild steel at a bend length of 1 inch across a 1 inch v die is about 0.79 ton or 1580lbs.

Our printers can directly form complex shapes directly from any 3d cad file. Using fdm 3d printing technology can be a great way to produce metal forming tools, such as those used for hydroforming an rubber pad pressing. I've detailed the process i took to design and get the forming (mostly) working in the video. 10.03.2020 · using 3d printed forms to bend sheet metal isn't exactly new. Our capability of low cost metal forming complex shapes out of thick plate is an. The force required to bend 10 gauge(0.134/3.4mm) mild steel at a bend length of 1 inch across a 1 inch v die is about 0.79 ton or 1580lbs. Our printers can directly form complex shapes directly from any 3d cad file. 3d metal forming is the global leader in metal forming of very large and complex, double curved, shapes for the aerospace, architectural and energy markets. Forming a replacement blade guard. Sheet metal forming with 3d printed dies. For the aerospace industry we form both near net shapes (preforms) out of thick plate and final product shapes out of sheet metal.

An expert in the field of metal forming, cincinnati inc., has tested their 3d printed tools up to 14ga steel and had success with 1000 bends. Our capability of low cost metal forming complex shapes out of thick plate is an. The end goal of this project was a replacement blade guard for a sawzall. The force required to bend 10 gauge(0.134/3.4mm) mild steel at a bend length of 1 inch across a 1 inch v die is about 0.79 ton or 1580lbs. An expert in the field of metal forming, cincinnati inc., has tested their 3d printed tools up to 14ga steel and had success with 1000 bends. Traditional metal manufacturing techniques include forming, casting, molding, joining, and machining. 10.03.2020 · using 3d printed forms to bend sheet metal isn't exactly new. Several specimens printed with different process parameters were tested to.